A difference you can feel.

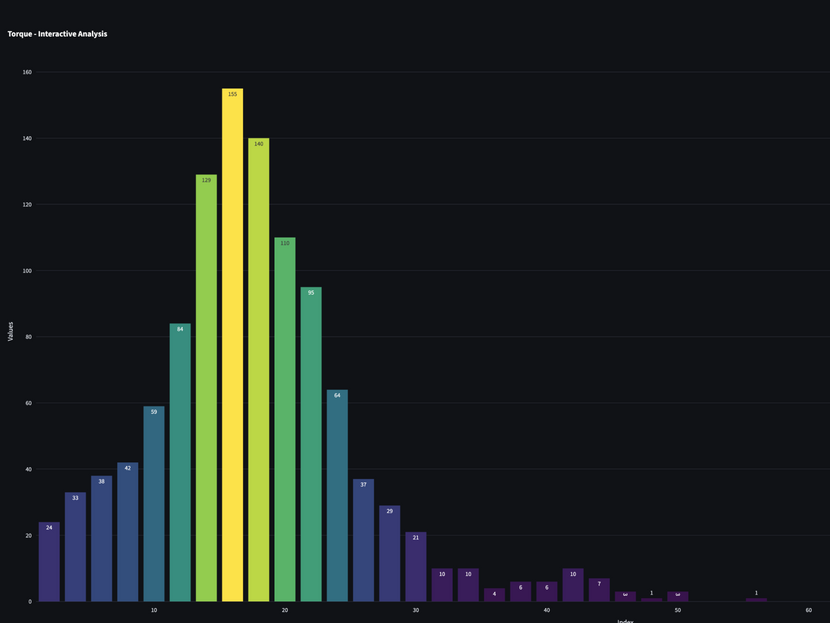

Bimotal’s powertrains deliver 43% more torque density than major competitors such as Bosch and Shimano.

Our team includes engineers from Tesla, Formula 1, and aerospace, with some of the sharpest minds developing high-performance hardware.

Electrify Your Ride

Elevate Powered Search & Rescue Saves Lives

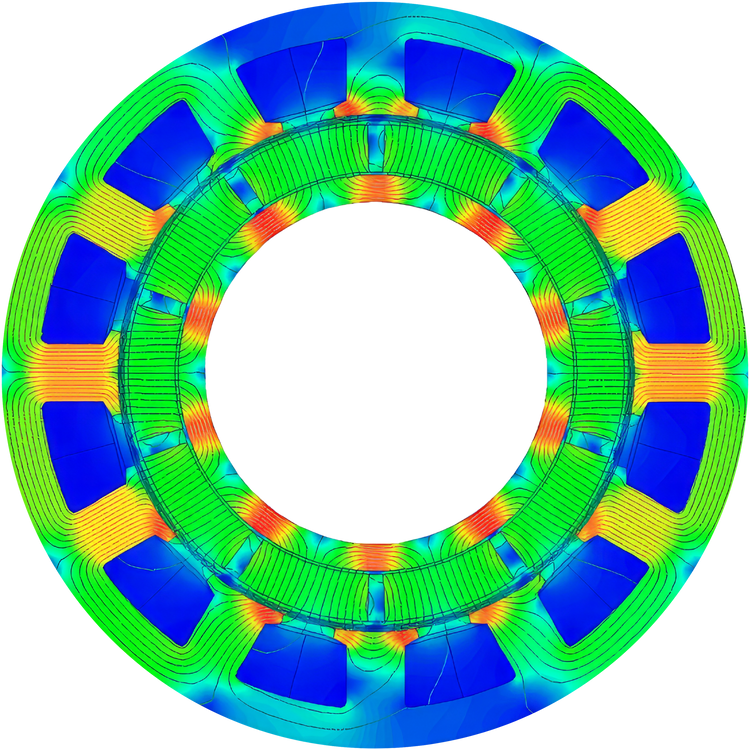

Made possible with proprietary gearbox layouts, highly optimized motors and power electronics.

Bimotal’s powertrains deliver 43% more torque density than major competitors such as Bosch and Shimano.

We wrote our own finite element code to simulate millions of motor designs. We selected the best motor of 85 million iterations for our flagship powertrain design.

Comparatively, Tesla’s Model 3 motor initially underwent two million.

OEM Collaboration

Bimotal's first products have focused on mobility; discussions with an autonomous guided vehicle (AGV) company revealed that our torque-dense drives are also a perfect fit for robotics and automation applications. Bimotal will power the next frontier of modular motors and motion control.

Lightweight strength for the skies.

Ultra-compact, high-torque actuators free up mass and volume in aircraft, eVTOL and UAV platforms. Our drives deliver incredible power density, enabling lighter control surfaces and increased flight time.

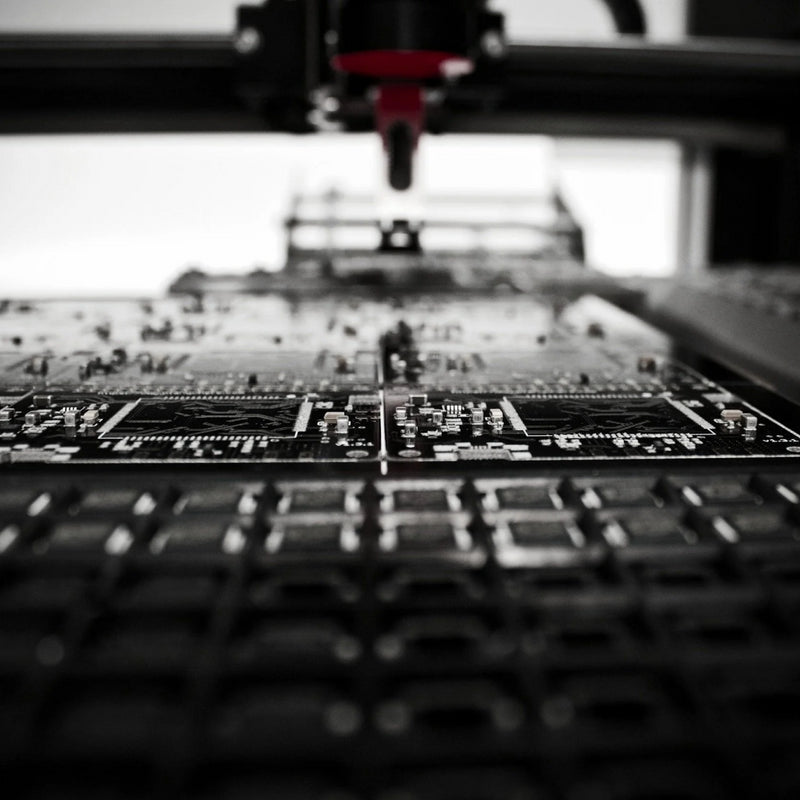

Automation powered by modular design.

We’ve developed custom mechanical and electrical interfaces for modular motors that can be moved from one platform to the next, unlocking unprecedented service and flexibility.

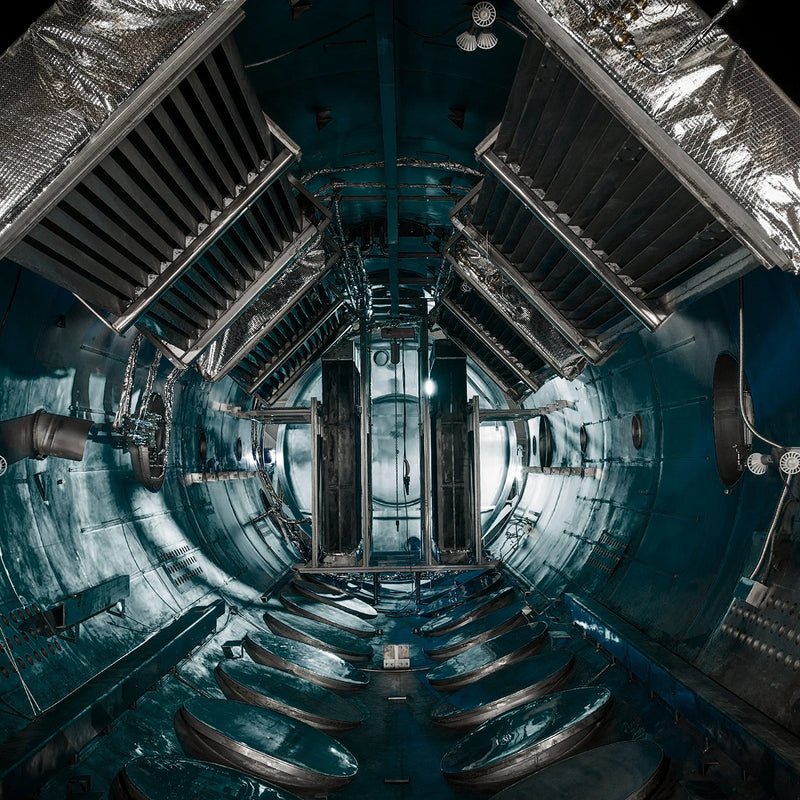

Uncompromising efficiency in zero gravity.

Accelerating space exploration drives the need for new e-machines optimized to work in a vacuum. No air means cooling is your top challenge: ultra-high efficiencies are required to make heat rejection manageable in space.

Learn more about our business solutions and consumer products

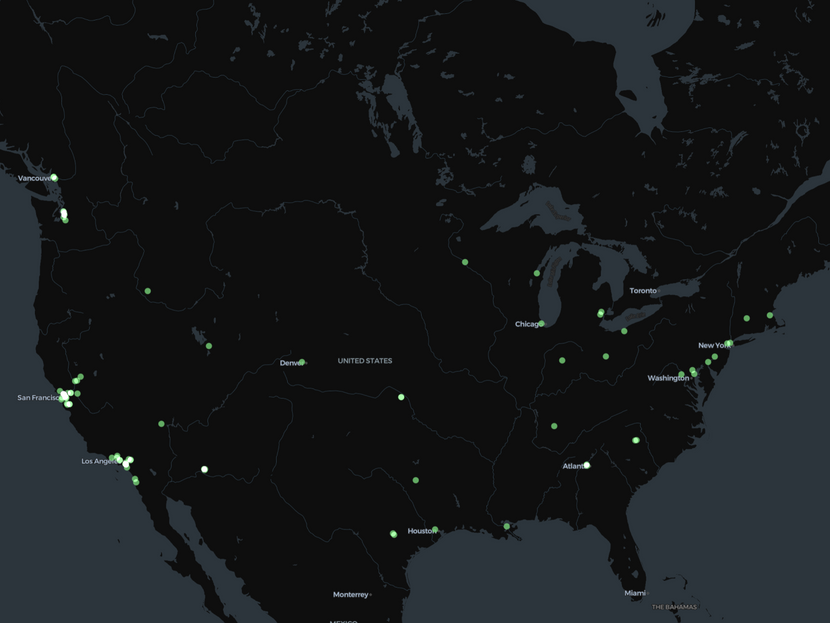

Motors, sensors, and accessories connect through our custom wireless platform designed to scale across machines and generations. We use real field data & AI-powered analytics to optimize our powertrains. The result: Lighter, more efficient, more reliable, and more capable drives.

Every Bimotal product can log and stream data to the cloud. Join a connected community that can share use cases, compete, and steer the course of new product features and improvements.

Over-the-air updates and real-world metrics ensure every unit in the field keeps getting better long after it ships.